Ungakhetha kanjani ukufakwa kwepayipi lensimbi engagqwali kwekhwalithi ephezulu (njengamandololwane ensimbi engagqwali)-umehluko phakathi kwesithando somlilo esiphakathi nendawo nesithando somlilo sokucwengisiswa

I-Abstract: Lesi sihloko sihlose ukusiza amakhasimende ukuthi afunde futhi ahlukanise phakathi kwamapayipi ensimbi engagqwali akhiqizwa izithando zomlilo eziphakathi nendawo namapayipi ensimbi engagqwali akhiqizwa iziko lokucwenga, ukuze akwazi ukukhetha ukufakwa kwamapayipi ensimbi engagqwali okusezingeni elingcono (njengezindololwane zensimbi engagqwali).

Njengamanje, amapayipi ensimbi engagqwali emakethe ngokuvamile ahlukaniswe ekukhiqizeni kwesithando somlilo kanye nokukhiqizwa kwesithando somlilo esiphakathi, ngakho-ke yini umehluko phakathi kwalokhu kokubili?

1. Izinqubo ezahlukene zokukhiqiza

Lapho kucwengwa amapayipi ensimbi engagqwali, isithando somlilo sokucwenga sizophephetha umoya-mpilo, amagesi angenayo i-argon (Ar) kanye ne-nitrogen (N2) ensimbi encibilikisiwe ukuze kuzuzwe umphumela we-vacuum wamanga, ozonciphisa okuqukethwe kwekhabhoni kumapayipi ensimbi engagqwali kube amazinga aphansi kakhulu. . , futhi ukufutha igesi engasebenzi ngesikhathi esifanayo kungase futhi kuvimbele i-oxidation yezinto ze-chromium alloy kunsimbi engagqwali.

Isithando somlilo esimaphakathi sidala inkambu kazibuthe ngokusebenzisa amandla ashintshanayo ukushisisa insimbi esithandweni sokwenza insimbi. Uma usebenzisa isithando somlilo esiphakathi ukukhiqiza amapayipi ensimbi engagqwali, okuqukethwe kwekhabhoni akukwazi ukuncishiswa futhi ukungcola akukwazi ukususwa.

2: Izici ezihlukile zokucubungula

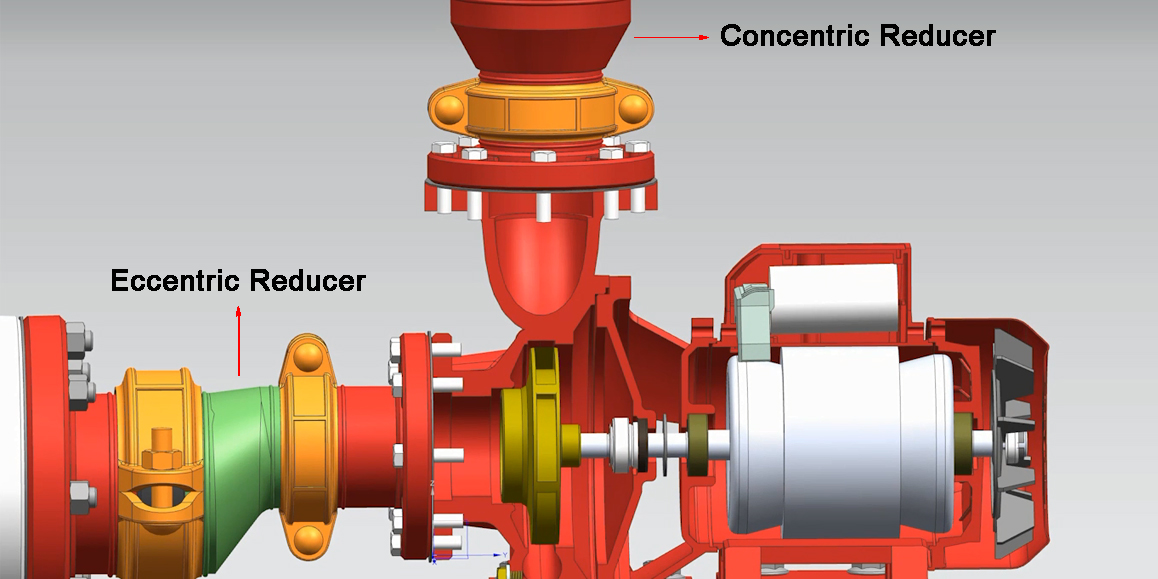

Amapayipi ensimbi engagqwali akhiqizwa isithando somlilo sokucwenga anokuqukethwe kwekhabhoni ephansi nokungcola okumbalwa, futhi akwazi ukugcina izakhi eziwusizo ezifana ne-chromium. Ngakho-ke, amapayipi ensimbi engagqwali akhiqizwa isithando somlilo sokucwenga ane-ductility ephezulu futhi angakwazi ukuqedela ngokuphelele ukucubungula okuyinkimbinkimbi njengokugoba, ukugoba, ukwandisa, ukuncipha, njll. , zingaba Qedela ukucutshungulwa kokupholishwa kwendawo okufunwa kakhulu kokufakwa kwamapayipi ensimbi engagqwali (njengamandololwane ensimbi engagqwali).

Amapayipi ensimbi engagqwali enziwe izithando zomlilo we-medium-frequency ane-ductility embi kanye nokusebenza kabi kokucubungula ekugobeni, ukugoba, ukunwetshwa, kanye nokuncipha. Okuqukethwe ukungcola emapayipini ensimbi engagqwali kuphezulu, futhi awakwazi ukuhlangabezana nezimfuneko zokupholishwa okuhle kokufakwa kwamapayipi ensimbi engagqwali yekhwalithi ephezulu (njengezindololwane zensimbi engagqwali).

Ezintathu: izinto zokusetshenziswa ezahlukene

Isithando somlilo sokucwenga singakwazi ukwenza insimbi yesibili, futhi ngokuvamile singangeza noma sinciphise izinto ezifanele ukuze kufezwe injongo yokucwenga, ngakho-ke insimbi engalahliwe nesihlabathi sensimbi ngokuvamile kusetshenziswa njengezinto zokusetshenziswa. .

Isithando somlilo esiphakathi singenza insimbi kanye kuphela, ikakhulukazi ngokwezinto ezingavuthiwe, ezingakwazi ukulawulwa ngendlela eguquguqukayo, ngakho-ke izinsalela zensimbi engagqwali nesihlabathi sensimbi ngokuvamile zisetshenziselwa ukuncibilikisa. Le ndlela yokuncibilikisa ayikwazi ukulawula okuqukethwe kwezakhi ezithile, ngakho ikhwalithi yomkhiqizo imbi kakhulu futhi ngokuvamile ayisetshenziswa ezimbonini zemikhiqizo ezifana nokucubungula okujulile.

I-Zhejiang Mingli Pipe Industry iyimboni yokufakwa kwamapayipi ensimbi engenasici yaseShayina eneminyaka engaphezu kwengu-30 yokukhiqiza kanye nesipiliyoni sokucubungula. Izinto zokusetshenziswa ziyi-100% yamapayipi ensimbi acwengekile, aqinisekisa ikhwalithi evela emthonjeni.