Izinhlobo zezinqubo zokukhiqiza zamaflange ensimbi engagqwali

I-flange yensimbi engagqwali iyingxenye ebalulekile yokuxhuma amapayipi nemishini. Inezici zokumelana nezinga lokushisa eliphezulu, ukumelana nokugqwala nokubekwa uphawu okuhle. Izinqubo ezivamile zokukhiqiza i-flange yensimbi engagqwali zihlukaniswa ikakhulukazi zibe izinhlobo ezine: ukubumba, ukuphonsa, ukusika, nokugingqa.

(1) Faka i-flange yensimbi engagqwali

Inqubo yokujova insimbi encibilikisiwe esikhunjini ukuze uphonsa ama-flange ensimbi engagqwali ibizwa ngokuthi indlela yokuphonsa. Izinzuzo yilezi: ukwakheka okunembile nosayizi wevolumu engenalutho, ivolumu encane yokucubungula, izindleko eziphansi, futhi isikhunta singashintshwa ngokuvumelana nezidingo zamakhasimende ukukhiqiza izimo eziyinkimbinkimbi. Ukungalungi: Ukulimala kokusakazwa (izimbotshana, ukuqhekeka, okufakiwe), ukwakheka okungekuhle kwangaphakathi kokusakazwa, amandla okugunda okungenamandla namandla aqinile. Yiqiniso, kukhona nezinqubo eziphakeme ze-cast stainless steel flange ezinganciphisa ukushiyeka okunjalo. Isibonelo, ama-flange ensimbi engenasici ayi-centrifugal awuhlobo lwama-flange ensimbi engagqwali. Indlela ye-centrifugal iyindlela yokuphonsa enembile yokukhiqiza ama-flange ensimbi engagqwali. Ama-flange ensimbi engagqwali asakazwa ngale ndlela mahle kakhulu kunamalungiselelo ajwayelekile okuphonsa isihlabathi, ikhwalithi ithuthukiswa kakhulu, futhi ayithambekele kangako ezinkingeni ezifana nezimbotshana, imifantu, kanye ne-trachoma.Okulandelayo incazelo enemininingwane yokusakazwa kwe-centrifugal yama-flange ensimbi engagqwali.

(2) I-Flange yensimbi engagqwali eyakhiwe

Ama-flange ensimbi engagqwali etholwe ngokuvamile anokuqukethwe kwekhabhoni ephansi kunama-flange ensimbi engagqwali futhi mancane amathuba okuthi agle. Ama-forging anama-streamlines amahle kanye nesakhiwo esiminyene. Izakhiwo zabo zemishini zingcono kunalezo zamaflange ensimbi engagqwali futhi zingamelana namandla aphezulu okugunda kanye nokungezwani. Isandiso.

Ama-flange ajwayelekile ensimbi engagqwali eyakhiwe ayakhiwa futhi ayakhiwe.

I-Forged flange iyi-flange eyakhiwe ngokushisa okushisayo kwezinto zensimbi bese ishaywa. Isici esiyinhloko sale nqubo ukusebenzisa izinga lokushisa eliphezulu nokucindezela okuphezulu ukuguqula kancane kancane izinto zensimbi ukuze ukwakheka nokusebenza kwayo kuthuthukiswe.

Umehluko phakathi kwe-flange engumgunyathi kanye ne-forged flange ukuthi isebenzisa ukusebenza komshini ukubumba izinto zensimbi, inqubo yokucubungula insimbi efana naleyo ye-flange engumgunyathi. Le nqubo ihlobene ne-forging deformation kunokufoja ngesandla.

Okulandelayo incazelo eningiliziwe yamaflange ensimbi engagqwali eyenziwe ngomgunyathi kanye namaflange ensimbi engenasici.

(3) Sika i-flange yensimbi engagqwali

Sika ngokuqondile ububanzi bangaphakathi nangaphandle be-flange kanye nogqinsi lwamadiski epuleti lensimbi engagqwali, bese ucubungula izimbobo zebhawodi nemigqa yamanzi. Usayizi wama-flange ensimbi engagqwali asikiwe futhi akhiqizwa ngokuvamile aweqi i-DN150. Uma usayizi udlula i-DN150, izindleko zizokhula kakhulu.

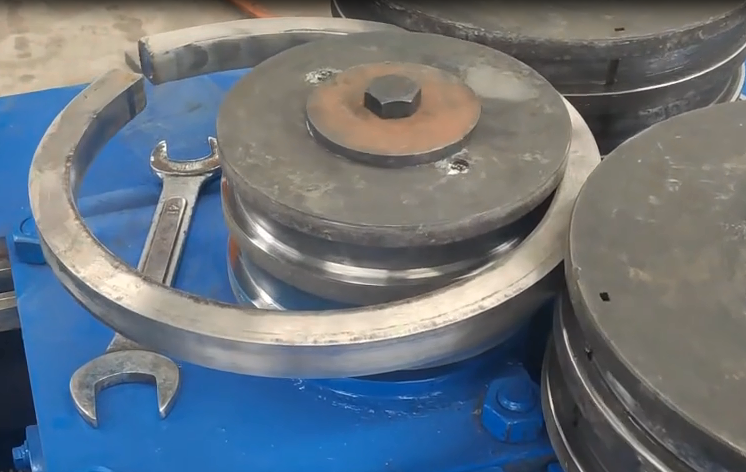

(4) I-flange yensimbi engagqwali egoqwe

Inqubo yokusika amapuleti aphakathi nendawo ensimbi engagqwali abe yimicu bese iwagoqa abe yindilinga isetshenziswa kakhulu ekukhiqizeni amaflange amakhulu ensimbi engagqwali. Ngemuva kokugoqa okuphumelelayo, i-welded, bese isicaba, bese kucutshungulwa izimbobo zomugqa wamanzi kanye ne-bolt. Ngoba impahla eluhlaza iyipuleti eliphakathi, ukuminyana kuhle. Inqubo yokushisela ekuxhumaneni kwe-flange egoqiwe ibaluleke kakhulu, futhi i-X-ray noma ukuhlolwa kwefilimu ye-ultrasonic kuyadingeka.