Ukuguquguquka Nokuqina KwamaFlange Ensimbi Engagqwali

Ama-flange ensimbi engagqwali ayingxenye ebalulekile ezinhlobonhlobo zezicelo zezimboni, ezihlinzeka ngokuxhumeka okuqinile nokuthembekile phakathi kwamapayipi, ama-valve nezinye izinto zokusebenza. Ukuguquguquka kwazo kanye nokuqina kwazo kuzenza zibe yinketho ethandwayo ezimbonini kusukela kuwoyela negesi kuya ekucutshungulweni kwamakhemikhali nokwelashwa kwamanzi. Kule bhulogi, sizohlola izinzuzo eziningi zamaflange ensimbi engagqwali kanye nokubaluleka kwawo kubunjiniyela besimanje.

Enye yezinzuzo eziyinhloko zama-flange ensimbi engagqwali ukumelana kwawo okuhle kakhulu nokugqwala. Lokhu kubaluleke kakhulu ezimbonini lapho izinto zokusebenza zichayeka kumakhemikhali anonya, amazinga okushisa aphezulu kanye nokucindezela okukhulu. Insimbi engagqwali yaziwa ngamandla ayo okumelana nokugqwala, okuyenza ibe ukukhetha okuthembekile kwama-flange adinga ukugcina ubuqotho bawo ezindaweni eziyinselele. Lokhu kumelana nokugqwala kusho nokuthi ama-flange ensimbi engagqwali anempilo ende yesevisi, okunciphisa isidingo sokushintshwa nokugcinwa njalo.

Ngaphezu kokumelana nokugqwala, ama-flange ensimbi engagqwali nawo ahlala isikhathi eside kakhulu. Bangakwazi ukumelana nemithwalo esindayo kanye nokucindezela okuphezulu ngaphandle kokuphazamisa ubuqotho babo besakhiwo, okubenza bafanelekele izicelo ezifunwayo. Lokhu kuqina kuwumphumela wamandla emvelo ensimbi engagqwali, okuvumela i-flange ukuthi igcine ukwakheka nokusebenza kwayo ngisho nangaphansi kwezimo ezimbi kakhulu. Ngakho-ke, ama-flange ensimbi engenasici avame ukusetshenziswa ezinhlelweni ezibucayi lapho ukwethembeka kubaluleke kakhulu.

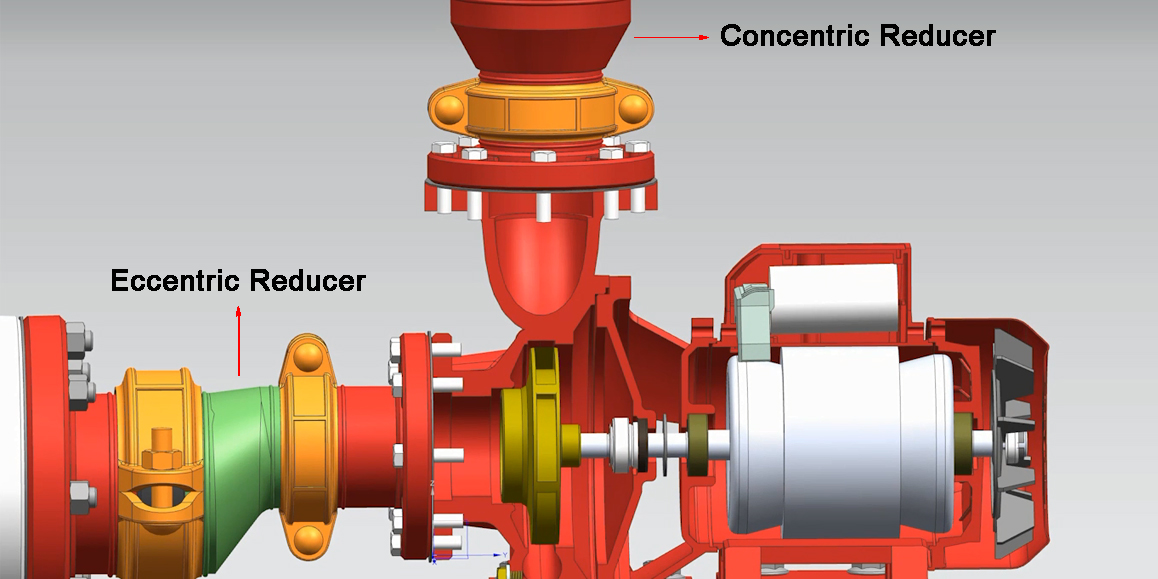

Enye inzuzo yama-flange ensimbi engenasici ukuguquguquka kwawo. Atholakala ngosayizi abahlukahlukene, izilinganiso zokucindezela nokucushwa, okwenza kube lula ukuthola i-flange elungile yohlelo lwakho lokusebenza oluthile. Noma ngabe i-lap flange, i-sleeve sleeve flange, i-butt welding flange noma i-socket welding flange, izinto zensimbi engagqwali zingahlangabezana nezidingo ezahlukahlukene zezimboni ezahlukahlukene. Lokhu kuguquguquka kwenza onjiniyela nabaklami bakwazi ukukhetha i-flange efaneleke kakhulu ngokusekelwe ezidingweni zabo ezithile, ukuqinisekisa ukusebenza kahle nokuphepha.

Ama-flange ensimbi engagqwali ayaziwa nangokufakwa kwawo kalula. Angashiselwa, abhowudwe noma acushwe amapayipi nezinto zokusebenza, anikeze ukuxhumana okuphephile, okungavuzi. Lokhu kufakwa okulula akugcini nje ukusindisa isikhathi nezindleko zabasebenzi, kodwa futhi kuqinisekisa ukuthi i-flange ifakwe ngendlela efanele, ukunciphisa ingozi yokuvuza nokuhluleka. Ngaphezu kwalokho, i-flange yensimbi engagqwali ingahlakazwa kalula futhi ifakwe kabusha, okwenza ukugcinwa nokulungiswa kube lula kakhulu.

Ngaphezu kwalokho, ama-flange ensimbi engagqwali ahambisana nemvelo. Insimbi engagqwali igaywa kabusha ngokuphelele, okuyenza ibe ukukhetha okusimeme kwezicelo zezimboni. Ngokusebenzisa ama-flange ensimbi engagqwali, izinkampani zingafaka isandla ekwehliseni umthelela wazo emvelweni futhi zithuthukise umnotho oyindilinga. Lokhu kuhambisana nokugxila okukhulayo kwemboni ekusimameni nasekukhiqizeni izinto ezinomthwalo wemfanelo.

Kafushane, ama-flange ensimbi engagqwali ahlanganisa ukuguquguquka, ukuqina nokumelana nokugqwala, okuwenza abe yingxenye ebaluleke kakhulu kubunjiniyela besimanje. Ikhono labo lokumelana nezimo ezinzima, ukuhlinzeka ngoxhumano oluvikelekile kanye neqhaza ekuzinzeni kubenza babe ukukhetha kokuqala kwezinhlobonhlobo zezicelo zezimboni. Njengoba imboni iqhubeka nokuthuthuka, ama-flange ensimbi engagqwali azoqhubeka nokuba yisici esibalulekile ekuqinisekiseni ukwethembeka nokuphepha kwezinhlelo ezibucayi.

Kungakhathaliseki ukuthi kusezindaweni ezihluzwayo, ezimbonini zamakhemikhali, ezindaweni zokuphehla ugesi noma ezikhungweni zokuhlanza amanzi, ama-flange ensimbi engagqwali adlala indima ebalulekile ekugcineni ubuqotho nokusebenza kwengqalasizinda yezimboni. Ukubaluleka kwabo akukwazi ukweqiwa, futhi ukusetshenziswa kwabo okuqhubekayo kubonisa ukuzethemba onjiniyela nabaklami abanako ekuthembekeni nasekuphumeleleni kwama-flange ensimbi engagqwali. Njengoba ubuchwepheshe buthuthuka kanye nezinselelo ezintsha zivela, ama-flange ensimbi engagqwali azoqhubeka ehamba phambili ekusungulweni nasekuthuthukeni embonini yobunjiniyela.