Iyini i-valve ye-butterfly yensimbi engagqwali?

Abstract: Lesi sihloko sethula kafushane isimiso sokusebenza, izigaba, okuhle nokubi, nezinkinga zamaphutha ezivamile zamavalvu ovemvane ensimbi engenasici, okuhloswe ngawo ukusiza wonke umuntu ukuthi afunde kangcono ngamavalvu ovemvane ensimbi engagqwali.

Amavalvu e-butterfly ensimbi engagqwali (abuye aziwe ngokuthi ama-stainless steel flap valves) amavalvu asebenzisa izingxenye ezimise okwediski ukuze aphindaphindeke ku-90° ukuze avule, avale, futhi alungise iziteshi eziwuketshezi. Njengengxenye esetshenziselwa ukuqaphela ukulawulwa kokuvala nokugeleza kwezinhlelo zamapayipi, ama-valve ovemvane ensimbi engagqwali angasetshenziswa ukulawula ukugeleza kwezinhlobo ezihlukahlukene zoketshezi olunjengomoya, amanzi, umusi, imidiya ehlukahlukene egqwalayo, udaka, imikhiqizo kawoyela, izinsimbi eziwuketshezi, kanye nemithombo ye-radioactive. Ikakhulukazi abamba iqhaza ekunqamuleni nasekushayeni amapayipi. Ama-valve e-butterfly ensimbi engagqwali asetshenziswe kabanzi emikhakheni eminingi efana ne-petroleum, imboni yamakhemikhali, i-metallurgy, kanye ne-hydropower.

Umgomo wokusebenza wamavalvu ovemvane ensimbi engagqwali

https://www.youtube.com/embed/mqoAITCiMcA?si=MsahZ3-CbMTts_i7

Amavalvu ovemvane ensimbi engagqwali, awaziwa nangokuthi ama-valve ensimbi engenasici, angamavalvu alawula insimbi engagqwali angasetshenziselwa ukulawula ukucima kwemidiya yamapayipi anengcindezi ephansi. Ikakhulukazi yakhiwe umzimba we-valve, isiqu se-valve, ipuleti levemvane, nendandatho yokuvala. Umzimba we-valve uno-cylindrical, ubude be-axial obufushane kanye nepuleti levemvane elakhelwe ngaphakathi.

Isimiso sokusebenza se-stainless steel butterfly valve ukufeza inhloso yokuvula nokuvala noma ukulungisa ngengxenye evulayo nevalayo (ipuleti levemvane elimise okwediski) elizungeza i-eksisi yalo emzimbeni wevalvu.

Izinzuzo kanye Nobubi Stainless Steel Butterfly Valve

Izinzuzo

1. I-torque encane esebenzayo, elula futhi esheshayo yokuvula nokuvala, 90° ukushintshanisa okuphindaphindayo, ukonga umsebenzi, ukumelana noketshezi oluncane, futhi ingasetshenziswa njalo.

2. Isakhiwo esilula, indawo encane yokufaka nesisindo esincane. Uma sithatha i-DN1000 njengesibonelo, isisindo se-stainless steel butterfly valve singaba ngu-2T ngaphansi kwezimo ezifanayo, kuyilapho isisindo se-valve yesango lensimbi engenasici singaba ngu-3.5T.

3. I-valve ye-butterfly kulula ukuyihlanganisa namadivayisi ahlukahlukene okushayela futhi inokuqina okuhle nokuthembeka.

4. Ngokusho kwamandla okubeka uphawu, ingasetshenziselwa imidiya enezinhlayiya eziqinile ezimisiwe, kanye ne-powdery ne-granular media.

5. Isiqu se-valve siwuhlaka lwe- through-stem, oluye lwaqina futhi lunezici ezinhle ezibanzi zemishini, ukumelana nokugqwala, nokumelana nokuhuzuka. Lapho i-valve ye-butterfly ivuliwe futhi ivaliwe, isiqu se-valve sijikeleza kuphela esikhundleni sokuphakamisa nokwehlisa. Ukupakishwa kwesiqu se-valve akulula ukonakala futhi uphawu luthembekile.

Ukubi

1. Ingcindezi yokusebenza kanye nebanga lokushisa elisebenzayo lincane, futhi izinga lokushisa elivamile lokusebenza lingaphansi kuka-300℃ nangaphansi kwe-PN40.

2. Ukusebenza kokubekwa uphawu kubi, okubi kakhulu kunamavalvu ensimbi yensimbi engagqwali kanye nama-stainless steel stop valves. Ngakho-ke, isetshenziswa ezindaweni ezinengcindezi ephansi lapho izidingo zokubeka uphawu zingekho phezulu kakhulu.

3. Ibanga lokulungiswa kokugeleza alilikhulu. Lapho ukuvulwa kufinyelela ku-30%, ukugeleza kungena ngaphezu kwe-95%;

Ukuhlukaniswa kwamavalvu evemvane ensimbi engenasici

A. Ukuhlukaniswa ngesakhiwo

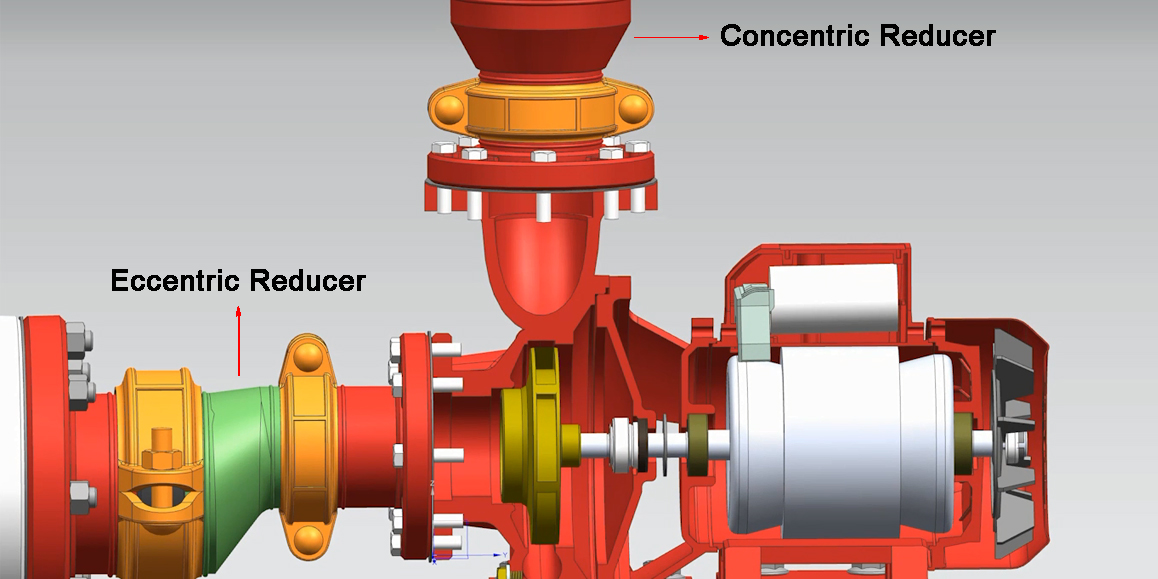

(1) Ivalve uvemvane evalwe maphakathi

(2) I-valve yamalahle evalwe nge-eccentric eyodwa

(3) I-valve uvemvane evalwe nge-eccentric kabili

(4) I-valve ye-stomp evalwe nge-eccentric kathathu

B. Ukuhlelwa ngokuvala impahla engaphezulu

(1) Soft-sealed stainless stainless stainless stainless valve valve, ehlukaniswe yaba izinhlobo ezimbili: impahla yensimbi engeyona eyensimbi kanye nempahla engeyona eyensimbi engeyona eyensimbi

(2) I-valve uvemvane yensimbi engenasici evalwe kanzima

C. Ukuhlukaniswa ngefomu lokuvala

(1) Ivalve uvemvane yensimbi engenasici ephoqelelwe

(2) I-valve ye-vavemvane yensimbi engenasici ene-elastic-sealed, ingcindezi yokuvala ikhiqizwa ukunwebeka kwesihlalo se-valve noma ipuleti le-valve lapho ivalvu ivaliwe.

(3) I-valve yovemvane yensimbi engenasici evalwe ngetorque yangaphandle, ingcindezi yokuvala ikhiqizwa itorque efakwa kushaft wevalvu.

(4) I-valve ye-butterfly yensimbi engenasici ecindezelwe, ingcindezi yokuvala ikhiqizwa into ecindezelwayo yokubopha uphawu esihlalweni sevalvu noma ipuleti levalvu.

5

D. Ukuhlukaniswa ngengcindezi yokusebenza

(1) Vacuum uvemvane lwensimbi engagqwali. I-valve uvemvane lwensimbi engagqwali enengcindezi yokusebenza ephansi kunomoya we-reactor ojwayelekile

(2) I-valve uvemvane yensimbi engenasici enengcindezi ephansi. I-valve ye-butterfly yensimbi engenasici ene-PN yengcindezi<1.6 MPa

(3) I-valve uvemvane yensimbi engenasici enomfutho omaphakathi. I-valve uvemvane lwensimbi engagqwali enengcindezi yokulinganisa engu-PN engu-2.5--6.4MPa

(4) I-valve yovemvane yensimbi engenasici enengcindezi ephezulu. I-valve ye-butterfly yensimbi engagqwali enengcindezi ebizwa ngokuthi i-PN engu-10.0--80.0MPa

(5) Ivalve uvemvane yensimbi engenasici enomfutho ophakeme kakhulu. I-valve ye-butterfly yensimbi engenasici ene-PN yengcindezi>100MPa

E. Ukuhlukaniswa ngezinga lokushisa lokusebenza

(1) I-valve ye-butterfly yensimbi engenasici, izinga lokushisa elisebenzayo: t>450 C

(2) I-valve ye-butterfly yensimbi engenasici, izinga lokushisa elisebenzayo: 120 C<t<450 C

(3) Izinga lokushisa elivamile ivalve uvemvane yensimbi engagqwali. Izinga lokushisa elisebenzayo: -40C<t<120 C

(4) Izinga lokushisa eliphansi le-valve uvemvane lwensimbi engenasici. Ibanga lokushisa elisebenzayo: -100<t<-40 C

(5) Izinga lokushisa eliphansi kakhulu lensimbi engenasici ye-butterfly valve. Ibanga lokushisa elisebenzayo: t<-100 C

F. Ukuhlukaniswa ngesakhiwo

(1) Offset plate steel stainless butterfly valve

(2) I-valve yovemvane yensimbi engagqwali mpo

(3) I-valve ye-butterfly yensimbi engagqwali egxilile

(4) I-Lever ye-butterfly valve yensimbi engagqwali

G. Ukuhlelwa ngendlela yokuxhuma(chofoza ukuze uthole ulwazi olwengeziwe)

(1) I-wafer yohlobo lwe-valve uvemvane lwensimbi engagqwali

(2) I-valve ye-butterfly yensimbi engenasici

(3) Uhlobo lwe-lug valve uvemvane lwensimbi engagqwali

(4) Ivalve uvemvane yensimbi engagqwali eshiselwe

H. Ukuhlelwa ngendlela yokudlulisela

(1) I-valve ye-butterfly yensimbi engenasici

(2) I-Gear drive butterfly valve yensimbi engagqwali

(3) I-valve yovemvane yensimbi engenasici yomoya

(4) I-hydraulic stainless steel stainless butterfly valve

(5) Isivalo sovemvane sensimbi engagqwali kagesi

(6) Electro-hydraulic linkage steel stainless butterfly valve

I. Ukuhlukaniswa ngengcindezi yokusebenza

(1) Vacuum uvemvane lwensimbi engagqwali. Ingcindezi yokusebenza iphansi kunomfutho womoya wenqwaba ojwayelekile

(2) I-valve ye-butterfly yensimbi engenasici enengcindezi ephansi. Ukucindezela okulinganiselwe kwe-PN

(3) I-valve uvemvane yensimbi engenasici enomfutho omaphakathi. Ingcindezi ebizwa nge-PN ingu-2.5-6.4MPa

(4) I-valve uvemvane yensimbi engenasici enomfutho ophezulu. Ingcindezi ebizwa nge-PN ingu-10-80MPa

(5) I-Ultra-high-high-high-pressure butterfly valve yensimbi engagqwali. Ukucindezela okujwayelekile okungu-PN>100MPa

Ukuthuthukiswa okuzayo kwe-stainless steel butterfly valve

Ama-valve evemvane ensimbi engenasici asetshenziswa kakhulu. Izinhlobonhlobo kanye nenani lokusetshenziswa kwayo kuyaqhubeka nokukhula, futhi ithuthukela ekushiseni okuphezulu, ukucindezela okuphezulu, ububanzi obukhulu, ukubekwa uphawu okuphezulu, impilo ende, izici ezinhle kakhulu zokulungisa, kanye ne-valve eyodwa enemisebenzi eminingi. Ukuthembeka kwayo nezinye izinkomba zokusebenza sezifinyelele izinga eliphezulu. Ngokusetshenziswa kwerabha yokwenziwa yamakhemikhali emelana nokugqwala kumavalvu ovemvane, ukusebenza kwamavalvu ovemvane ensimbi engagqwali kuye kwathuthukiswa. Ngoba irabha yokwenziwa inezici zokumelana nokugqwala, ukumelana nokuguguleka, ukuzinza kobukhulu, ukuqina okuhle, ukwakheka okulula, izindleko eziphansi, njll., kanye nerabha yokwenziwa esebenza okuhlukile ingakhethwa ngokuya ngezidingo ezahlukahlukene zokusetshenziswa ukuze kuhlangatshezwane nezimo zokusebenzisa ama-valve ovemvane. . Njengoba i-polytetrafluoroethylene (PTFE) inokumelana nokugqwala okuqinile, ukusebenza okuzinzile, akulula ukuguga, i-coefficient ephansi yokungqubuzana, ukwakha kalula, usayizi ozinzile, futhi ingagcwaliswa futhi yengezwe ngezinto ezifanele ukuze kuthuthukiswe ukusebenza kwayo okuphelele, ukuvala uphawu lwe-butterfly yensimbi engagqwali. impahla enamandla angcono kanye ne-coefficient ephansi ye-friction ingatholakala, inqobe ukulinganiselwa kwerabha yokwenziwa. Ngakho-ke, izinto eziphakeme ze-polymer zamangqamuzana ezimelelwe i-polytetrafluoroethylene kanye nokugcwaliswa kwayo kanye nezinto ezishintshiwe zisetshenziswe kabanzi kuma-valve butterfly ensimbi engagqwali, ngaleyo ndlela kuthuthukiswe ukusebenza kwama-valve ovemvane ensimbi engenasici kanye nokukhiqiza ama-valve ensimbi engenasici anezinga lokushisa elibanzi nokucindezela, ukubekwa uphawu okuthembekile. ukusebenza kanye nempilo ende yesevisi.

Ngokusetshenziswa kokumelana nokushisa okuphezulu, ukumelana nokushisa okuphansi, ukumelana nokugqwala okuqinile, ukumelana nokuguguleka okuqinile namandla aphezulu engxube ye-alloy kuma-valve ovemvane ensimbi engagqwali, ama-valve uvemvane ensimbi engenasici asetshenziswe kabanzi ekushiseni okuphezulu naphansi, ukuguguleka okuqinile, isikhathi eside. impilo kanye nezinye izimboni, nobubanzi obukhulu (9~750mm), umfutho ophezulu (42.0MPa) kanye nezinga lokushisa elibanzi (-196~606 ℃) amavaluve ensimbi engagqwali uvemvane avele, okuletha ubuchwepheshe bamavalve uvemvane ensimbi engagqwali entsha. izinga.

Amaphutha ensimbi engagqwali ajwayelekile

I-elastomer yerabha kuvalvu uvemvane izodabula, iguge, iguge, ibhoboze noma siwe ngesikhathi sokusetshenziswa okuqhubekayo. Inqubo yendabuko ye-hot vulcanization inzima ukuzivumelanisa nezidingo zokulungiswa kwendawo. Imishini ekhethekile kumele isetshenziselwe ukulungisa, edla ukushisa nogesi okuningi, futhi idla isikhathi futhi idinga umsebenzi. Namuhla, izinto ezihlanganisiwe ze-polymer zisetshenziswa kancane kancane esikhundleni sezindlela zendabuko, phakathi kwazo ezisetshenziswa kakhulu uhlelo lobuchwepheshe lwe-Fushilan. I-adhesion ephakeme kanye nokumelana okuhle kakhulu kokuguga nokukhala kwemikhiqizo yayo kuqinisekisa ukuthi impilo yesevisi yezingxenye ezintsha ifinyelelwa noma idlule ngisho nangemva kokulungiswa, kufinyeza kakhulu isikhathi sokuphumula.

Amaphuzu abalulekile okukhethwa nokufakwa kwama-valve e-butterfly ensimbi engagqwali

1. Indawo yokufaka, ubude, nezikhombisi-ndlela zokungena neziphumayo zamavalvu ovemvane ensimbi engagqwali kufanele kuhlangabezane nezidingo zedizayini, futhi ukuxhumana kufanele kuqine futhi kuqine.

2. Kuzo zonke izinhlobo zama-valve okwenziwa ngesandla afakwe kumapayipi afakwe i-insulated, izibambo akufanele zibheke phansi.

3. Ukubukeka kwevalvu kufanele kuhlolwe ngaphambi kokufakwa, futhi ipuleti legama levalvu kufanele lihambisane nezinhlinzeko zezinga likazwelonke lamanje elithi "General Valve Marking" GB 12220. Kumavalvu anengcindezi yokusebenza engaphezu kuka-1.0 MPa namavalvu lawo ukusika ipayipi eliyinhloko, amandla kanye nokuhlolwa okuqinile kokusebenza kufanele kwenziwe ngaphambi kokufakwa, futhi kungasetshenziswa kuphela ngemva kokuphumelela ukuhlolwa. Ngesikhathi sokuhlolwa kwamandla, ingcindezi yokuhlola iphindwe izikhathi ezingu-1.5 ingcindezi encane, futhi ubude besikhathi abukho ngaphansi kwemizuzu emi-5. Izindlu zama-valve kanye nokupakishwa kufanele kungavuzi ukuze zifaneleke. Ngesikhathi sokuhlolwa kokuqina, ukucindezela kokuhlola kuyizikhathi ezingu-1.1 ukucindezela okujwayelekile; ingcindezi yokuhlola ngesikhathi sokuhlolwa kufanele ihlangabezane nezidingo ze-GB 50243 ejwayelekile, futhi indawo yokuvala i-valve disc kufanele ingavuzi ukuze ifaneleke.

4. Ama-valve e-Butterfly afanele ukulawulwa kokugeleza. Njengoba ukuncipha komfutho wamavalvu ovemvane epayipini kukhulu uma kuqhathaniswa, cishe ngokuphindwe kathathu kunamavalvu esango, lapho kukhethwa amavalvu ovemvane, ithonya lokulahlekelwa kwengcindezi ohlelweni lwamapayipi kufanele licatshangelwe ngokugcwele, namandla epuleti lovemvane ukuze limelane. ukucindezela okuphakathi kwamapayipi lapho ivaliwe kufanele kucatshangelwe. Ukwengeza, umkhawulo wokushisa osebenzayo we-elastic valve seat material ekushiseni okuphezulu kufanele ucatshangelwe.

Isiphetho

Ngokuvamile, i-stainless steel flange butterfly valve ingumkhiqizo we-valve onokusebenza okuphezulu nokusebenza okubanzi, ofanele ukulawula uketshezi emikhakheni ehlukahlukene yezimboni. Lapho ukhetha futhi uyisebenzisa, izici zayo kanye nezidingo zohlelo lokusebenza kufanele zicatshangelwe ngokugcwele, futhi imininingwane efanele kanye nemikhiqizo kufanele kukhethwe ukuze kuqinisekiswe ukuzinza nokuphepha kokusebenza kwemishini.